Maintenance Service

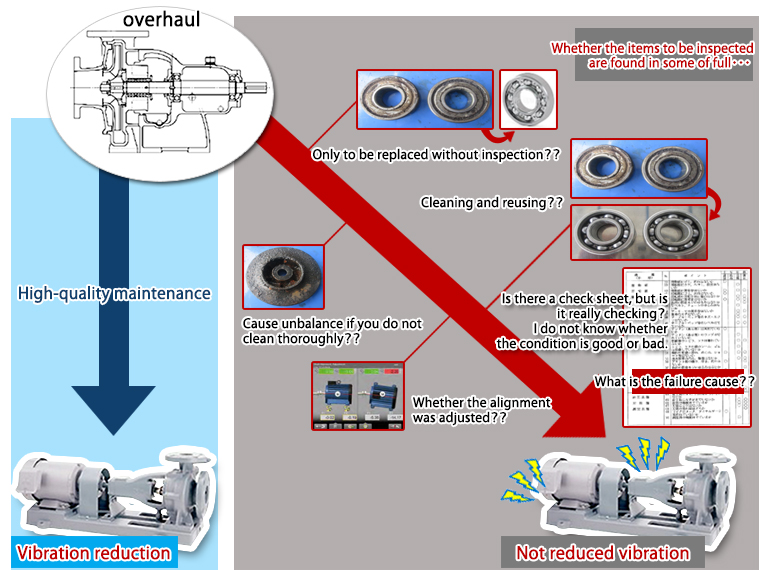

In our factory we wonder if maintenance is made properly ・・・???

■For example, pump

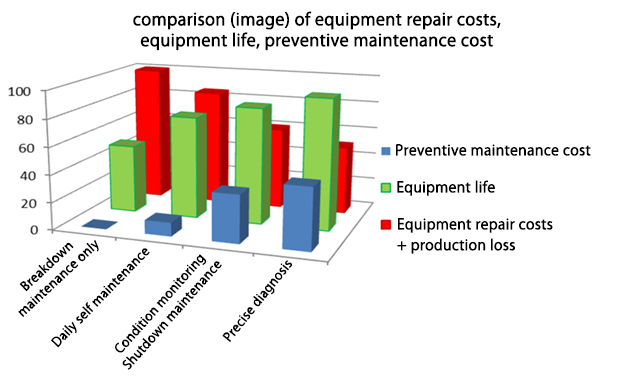

No matter how cheap the maintenance cost per unit, this not only increases the frequency of maintenance but also stresses the machine and shortens to machine life. Also, energy loss due to increased load will also occur.

Preventive maintenance (monitoring) finds breakdown beforehand, Predict lifespan, maintenance at appropriate cycle.

|

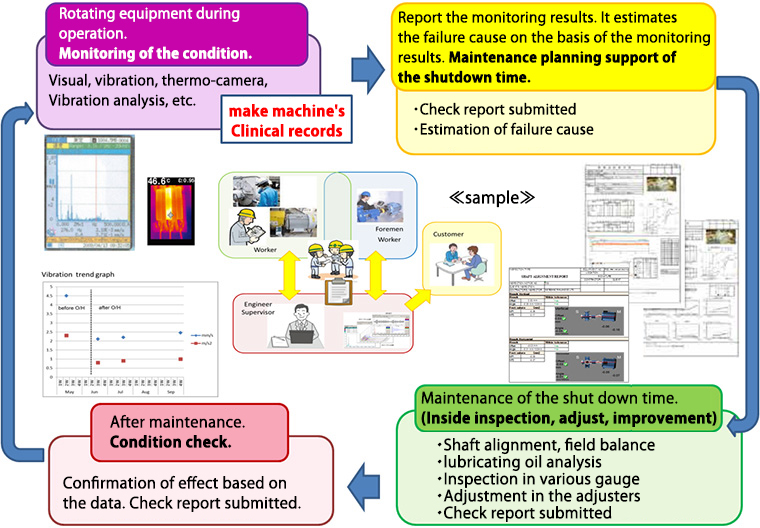

Our company can totally support the maintenance of rotating equipment. |

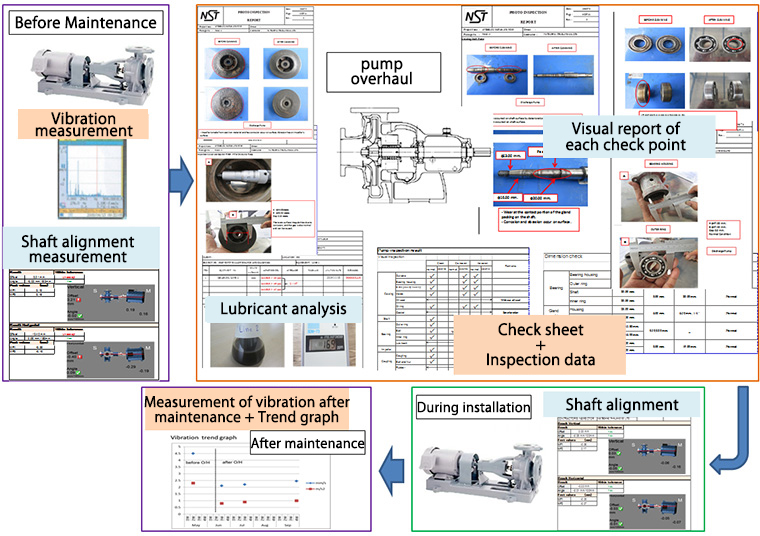

We will submit the "easy-to-understand" report.

Our maintenance is provided in a package including all monitoring,

analysis and adjustment.

Preventive maintenance support course (Operation time monitoring) diagnosis of rotating equipment

|

Course |

Checking method |

Submit reports | |

|

Simple check |

Vibration meter, thermo-scan |

Inspection check sheet |

|

|

Precise analysis |

Vibration analysis(Frequency analysis), |

Vibration measurement data |

|

|

Package |

Simple diagnosis + Precision analysis |

||

We can handle a wide range of maintenance services including monitoring and cleaning of equipment and parts, inspection, lubricant change, maintenance, repair, remodeling.

|

◆Rotating equipment |

|

Pumps, Blowers, Various conveyors, Agitators, Mixers, Pulverizers, Classifiers, Rotary kilns, Gearboxes, Motors, etc. |

|

We offer total packages, such as monitoring, release check, correction, analysis of defects, and services for each item. |

|

◆Other |

|

Dust collector, Heat exchanger, Various furnaces, Dryer, Tank, Hydraulic / Pneumatic cylinders, etc. |

|

We are even possible also quote in only cleaning and inspection. |