What is Lost Wax Casting?

Lost wax casting is a type of metal casting method that offers the greatest flexibility in shape and material.

Our lost wax casting technology is selected by various industries such as food, packaging, semiconductors, etc., as well as general industrial equipment.

Features of our Lost Wax Casting

|

| Shape |

More flexible in shape compared to other manufacturing methods |

| Material |

Various types of steel, stainless steel, and aluminum |

| Quantity |

Small to large lots (tens to thousands of pieces) |

| Casting surface |

Approx. 12.5a (depending on product size and casting material) |

| Accuracy |

Higher dimensional accuracy compared to sand casting. Less machining is required, thus reducing machining costs and time. |

|

Classification

|

Material

|

|

Stainless Steel

|

SUS303(Lostwax), SCS13, SCS14,

SCS2A, SUS440C, SCS24

|

|

Carbon Steel

|

S25C(Lostwax), S45C(Lostwax)

|

|

NiCrMo Steel

|

SNCM439(Lostwax)

|

|

CrMo Steel

|

SCM415(Lostwax), SCM435(Lostwax), SCM440(Lostwax)

|

|

Tool Steel

|

SK85(Lostwax), SKH57(Lostwax), SKS3(Lostwax), SKD11(Lostwax),

SKD61 (Lostwax)

|

|

Heat Resisting Steel

|

SCH22

|

|

Aluminum

|

AC4C, AC7A

|

|

|

|

Linear Tolerance(mm)

|

|

Dimensions

|

General

|

|

Over

|

To

|

|

-

|

25

|

±0.3

|

|

25

|

50

|

±0.6

|

|

50

|

75

|

±0.8

|

|

75

|

100

|

±1.0

|

|

100

|

125

|

±1.3

|

|

125

|

-

|

±1.5%

|

|

Angle Tolerance

|

±1.5°

|

|

|

Mold manufacturing cost is extremely low (about 1/5 of molds for plastic parts), and once made, the molds can be used semi-permanently.

|

Prototyping, Small Lot Production

Due to low mold cost, the cost per product is definitely lower than other manufacturing methods.

Mass Production

We can offer low price by selecting the best solution for each product.

|

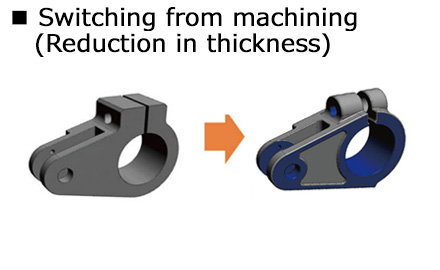

Machining is eliminated or greatly reduced. Cost advantage is significant for difficult to machine materials.

|

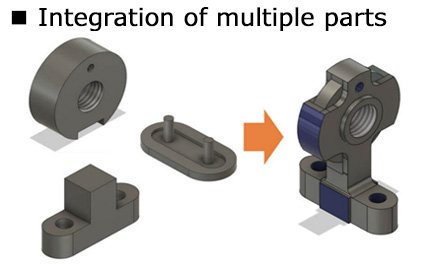

Assembly parts that are composed of multiple parts can be integrated into a single part, resulting in significant cost reductions.

|

Lost Wax Casting Product Examples

|

|

Body

|

Material:

|

SCS13

|

|

Size:

|

φ88 × 37t |

|

Industry:

|

Valve equipment

|

|

Slide plate

|

Material:

|

SKS3 (precision casting)

|

|

Size:

|

R110 50° |

|

Industry:

|

Food equipment

|

|

|

Side stand braket

|

Material:

|

S25C (precision casting)

|

|

Size:

|

77×72×49.5 |

|

Industry:

|

Motorcycle equipment

|

|

Clamp yoke

|

Material:

|

S45C (precision casting)

|

|

Size:

|

62×54×30 |

|

Industry:

|

Engine equipment

|

|