Dydo-Tec Co.,Ltd

An expert on Anodizing and Surface treatment

|

Please contact us first!

Anodizing problem-solving examples.

1. Lubrication function for rice milling machine |

As shown in the illustration on the right above, rice polishing machines have a slide called a chute. This component facilitates the movement of rice for selection purposes.

We collaborated with the customer to find the optimum condition by repeatedly trying out subtle changes in how the rice slides. We not only adjusted the subtle differences in how the rice slides but also worked patiently on issues such as stains and unevenness on the surface. We chose lubricants and developed a process to meet these specifications.

2. Anodizing of long (4.0m) aluminum pipe |

In-house design > We try to improve the number of jigs and the installation time for each jig by repeatedly trying various methods to realize the QCD required by the customer. We can also manage bent pipes as shown in the photo below.

3. Adjusting the accuracy and dimensions of ultra-precise products after anodizing and coloring |

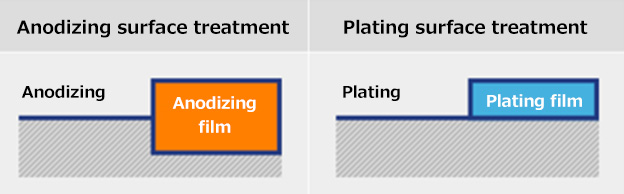

Anodizing of precision screw parts adheres to the surface and penetrates the material. Generally, it is said that the film thickness is 50% to 50%, but since the film thickness varies depending on the conditions, we work with our customers to fine-tune their cutting dimensions while also taking into account the variation in the thickness of the anodizing film in order to meet their required dimensions.

4. Coloring of decorative items, gloss, and color matching |

Certain customers have color specifications for decorative items. Colors vary depending on each person's sensibility. We respond to customer requirements by controlling both visual judgment and numerical values of color using a color difference meter.

In addition, during mass production, the quality of the dyeing solution changes from moment to moment, so we manage trends accordingly.

Together with our customers, we establish shared quality criteria and produce according to these standards, including color shades based on limit samples.

5. Sample support, urgent response for those who need it in the morning for night delivery |

We proactively respond to emergency requests by making flexible production that is easy to adapt to, taking advantage of our company's unique features of semi-automatic/manual production and in-house manufacturing of bathtubs and jigs.

1. Emergency response for a single equipment part

2. Emergency response due to delayed shipments from overseas

3. Emergency response due to sudden defects

All employees are committed to improving customer satisfaction as part of our company culture. We have maintained timely deliveries for years and ensure overtime or holiday work meets customer needs.