Dydo-Tec Co.,Ltd

An expert on Anodizing and Surface treatment

What is anodizing?

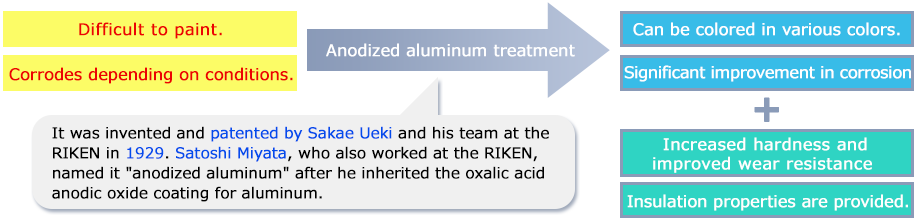

Characteristics of aluminum base material |

|

| |||||||||||||||||||||

►A method to improve the shortcomings of aluminum |

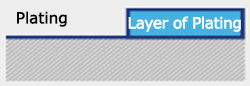

Difference from plating |

Different ① Whereas plating is simply a film that builds up on the base material, anodizing penetrates the base material and forms a film, producing a durable coating. Different ② Anodizing forms a metal film using the anode, while plating uses the cathode in a water tank. |

|

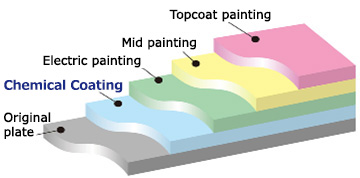

Difference from chemical coating |

Different ① Chemical coating involves submerging metal in an acidic or alkaline solution without using electricity. This method produces a chemical layer that enhances rust prevention and facilitates subsequent painting. Different ② Chromium is used to treat metals such as steel, zinc, and aluminum due to its hardness and corrosion resistance. |

|

Types and characteristics of anodizing |

Name | Sulfuric acid anodizing | Oxalic acid anodized aluminum | Chromic anodizing | Phosphate anodizing |

Solution type | Sulfuric acid | Oxalic acid | Chromic anhydride | Phosphoric acid |

Characteristics | High hardness / Abrasion resistance / Corrosion resistance / Weather resistance | High hardness / Abrasion resistance / Corrosion resistance / Weather resistance | High heat / Crack-free / Corrosion resistance | Corrosion resistance / Adhesion |

Component use | Digital cameras / Smartphone exteriors / Aircraft | Golden colored kettle pot | Aircraft parts | Painting / Adhesive Base |

Features | Sulfuric acid anodizing is a common method that results in minimal surface roughness. It can take advantage of the texture of the base material and can be colored in a variety of ways. | Oxalic acid anodized aluminum is more corrosion resistant than sulfuric acid anodized aluminum. As the film thickness increases, it exhibits excellent insulation properties. | A processing method that creates an aluminum film by immersing the material in a chromic acid solution. It can give high-strength aluminum alloys with high copper content, excellent corrosion resistance and heat resistance. This material is recognized for its durability and resistance to cracking or breaking, making it suitable for applications such as airplane components. | This is done as a pretreatment to improve painting and adhesive strength. When anodizing with phosphoric acid liquid, the pore size becomes larger than with general anodizing, making it easier to color. |