DIPSOL (THAILAND) CO.,LTD.

Manufacturing and sales of metal surface treatment agents

Product Introduction |

Additive Base Brightener |

|

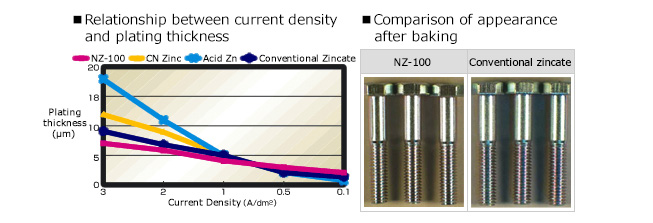

■ NZ-100 Features |

・Excellent high temperature resistance、no change in appearance due to baking treatment.

■ NZ-200, NZ-110 Features |

・Good uniform electrodeposition 、no change in appearance due to baking treatment.

■ NZ-750 Features |

・High-speed plating (0.4 μm/min or more) is possible with high zinc concentration, high current density and high temperature.

These barrel type brightener are ideal for plating bolts.

Clear type, Black type Black type |

|

■ ZTB-447 Process features |

・Cr6+ free, high corrosion resistance is obtained without overcoat.

・It has excellent heat and corrosion resistance.

・It can be used for long-term ,without renewal ( just consideration dilution cut bath ), so it is possible to reduce costs.

■ ZTB-447 Corrosion resistance test results by salt spray test |

Nickel-phosphorus alloy plating |

|

■ NP-1900 Features |

●uses hypophosphite as a reducing agent.

●It does not contain harmful heavy metals.

●It has excellent adhesion, and glossiness, and has good corrosion resistance at the edges.

●It is easy to handling of the plating bath and can be used stably for a long time.

■ Film properties |

■ Pretreatment product |

【Product】

Alkaline Electrolytic Cleaner

NC-20 (It has excellent degreasing and de smutting power)

Rust removal and rust removal accelerator for steel materials

V-3 (additive for acids pickling process)

Smut remover for steel parts

VC-12 (Remove strong dirt such as baking oil, carbon film, and smut)

■ Trivalent chromium (Cr3+ ) conversion |

【Product】

ALT-610 (Trivalent chromium conversion agent for aluminum and aluminum die casting)

■ ALT-610 Features |

・Stable corrosion resistance.

・Conventional processing equipment.

・No corrosion resistance deteriorate after heat treatment.

・Colorless - light yellow film for excellent adhesion of the coating film.

■ Corrosion resistance test results by salt spray test ( SST ) |