Case Study

|

Fluororesin coating |

Case1Coating on a die for hot plate welding (automobile parts)

|

■ Suggestions |

Case2Coating on mold for automobile parts (for body)

|

Case3Coating on a mold for a tractor seat

|

■ Suggestions ■ Result |

Case4Scratch protection coating for automobile bumper (200㎛ acrylic resin coating)

|

Case5Coating on rubber mold

|

■ Content of request ■ Proposal contents ■ result ■ problem |

Case6Coating on rubber mold (injection molding)

|

■ Content of request ■ Proposal contents ■ result |

Case7Coating on diaphragm mold

|

■ Content of request ■ Proposal contents |

Case8Coating on crawler mold

|

■ Proposal contents ■ result

|

Case9Coating on fingerstall mold

|

■ Content of request ■ Proposal contents |

Case10Molds for industrial gloves

|

■ Content of request ■ Proposal contents ■ result |

Case11Mold of shoe sole

|

■ Proposal contents |

Example12Coating of toothbrush case on mold (vacuum molding)

|

Case13Coating the watch mold

|

■ Content of request ■ Proposal contents |

Example14Coating on a tennis ball mold

|

|

Case15Coating on sports ball mold

|

■ Content of request ■ Proposal contents ■ result |

Example16Diving, coating on mold for leisure goods

|

|

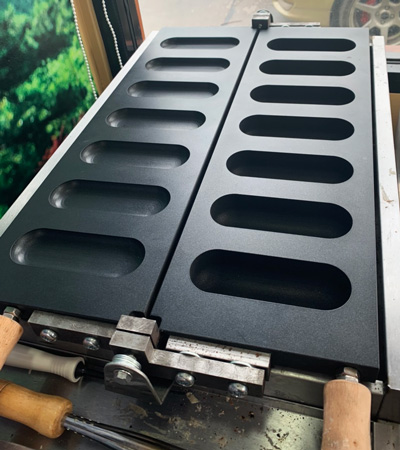

Example17Coating on a large-format baking mold

|

■ Suggestions |

Case18Coating on mold for manufacturing wheels

|

■ Proposal contents |

Case19Coating on Adhesive Jig

Before coating  After coating |

■ Content of request ■ Proposal contents |

Case20Coating on tire vulcanizing jig (bead ring)

|

■ Content of request ■ Proposal contents ■ result |

Example21Coating on plating jig

|

|

Case22Equipment fixture - Guide parts

|

■ Proposal contents |

Case23Study 3ABS Resin Coating on Fusion Blade

|

■ Content of request ■ Proposal contents |

Case24Coating on fusing blade

|

Case25Factory equipment (cutter)

|

■ Proposal contents ■ result

|

Case26Factory equipment (coolant)

|

■ Proposal contents ■ result |

Case27Coating on a carbon plate of a restaurant specializing in cooking

|

■ Suggestions |

Case28Microwave oven grill

|

■ Proposal contents |

Case29Coating on funnel for adhesive for rubber

|

■ Proposal contents ■ result |

Case30Calendar roll for rubber processing

|

■ Content of request ■ Proposal contents ■ result

|

Case31Coating on suction roll for sanitary products

|

■ Content of request ■ Proposal contents |

Case32Equipment of chemical factory

|

■ Suggestions

|

Case33Coating on Tanks for Chemicals

|

■ Content of request ■ Proposal contents ■ result |

Case34Spray grill

|

■ Proposal contents |

Case35Cleaning tray for precision parts

|

■ Proposal contents ■ result |

Case36Coating to wash basket

|

■ Proposal contents

|

Case37Coating a cleaning basket

|

|

Composite coating |

Case1Coating on clamp ring used in tire manufacturing process

|

■ Content of request ■ Proposal contents |

Case2Lifespan of mold life of tennis ball mold

|

■ Content of request ■ Proposal contents |

Case3Increasing durability of hot plate welding plates for automobile parts

|

■ Content of request ① ■ Proposal contents |

|

■ Content of request ② ■ Proposal contents |

|

Uneven non-stick coating |

Case1Non-stick coat at place where adhesive is used

Roll surface |

■ Content of request ■ Proposal contents ■ result |

Case2Non-stick coat at place where adhesive is used

|

■ Content of request ■ Proposal contents

|

|

Lubricating plating / lubricating coating |

Case1Spool Bush of Plastic Forming Machine

|

■ Proposal contents

|

Case2Tire Manufacturing Equipment Parts

|

■ Proposal contents ■ result

|

Case3Turbo engine gasket

|

■ Proposal contents |